Analysis of Magnesium Sulfate Board Strength

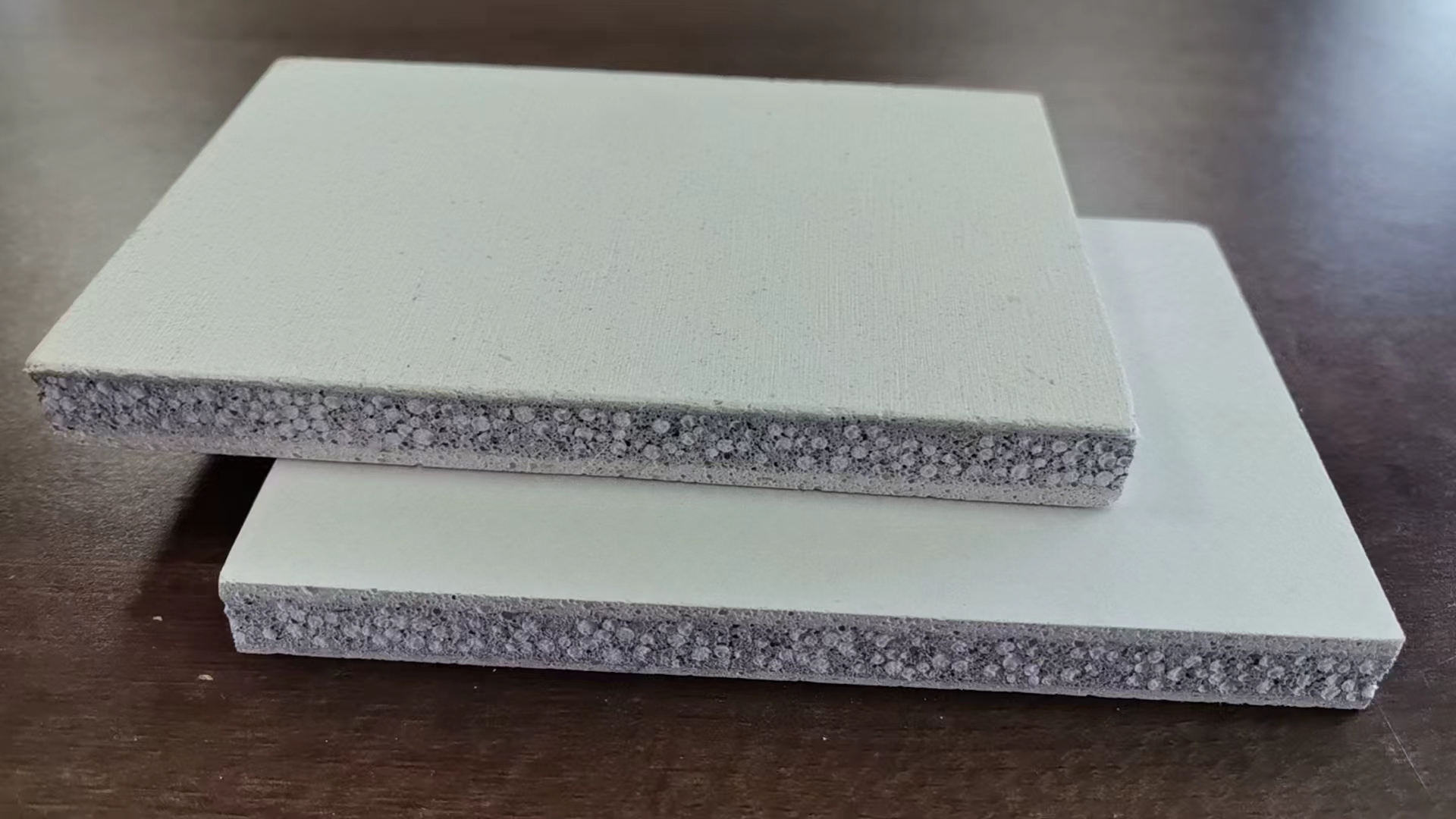

Magnesium sulfate board (MSB) is a type of cementitious panel that derives its strength from a complex and synergistic combination of its chemical matrix and physical reinforcement. Its strength is not from a single source but from the interplay of the following key factors:

1. The Chemical Matrix: The Magnesium Oxysulfate (MOS) Cement System

The primary source of strength in MSB is the hardened crystalline structure formed by the reaction between magnesium oxide (MgO) and magnesium sulfate (MgSO₄) solution.

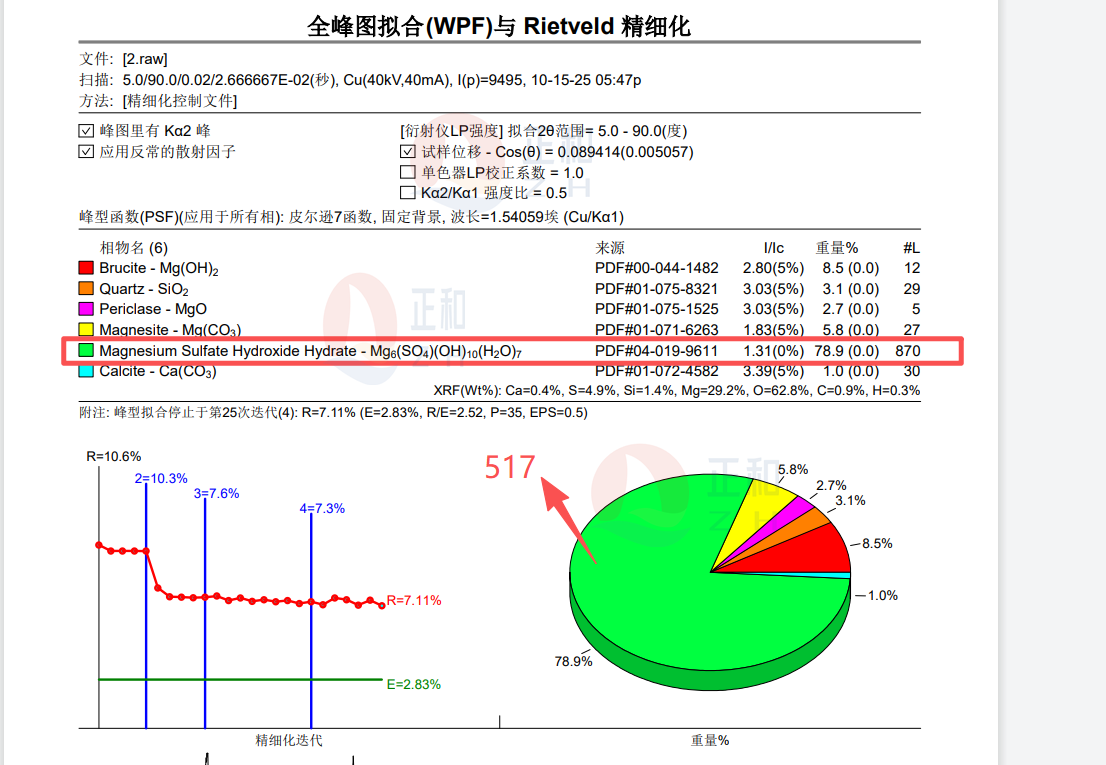

Crystalline Formation: When active MgO (derived from calcined magnesite) reacts with a magnesium sulfate solution, it forms a complex network of crystalline phases. The most important for strength is the 5·1·7 phase (5Mg(OH)₂·MgSO₄·7H₂O). This phase consists of interlocking, needle-like crystals that create a dense, rigid, and strong micro-structure.

Cohesive Binding: This crystalline network acts as a cohesive binder, locking the other components (fillers, fibers) firmly in place. The density and integrity of this crystal matrix are fundamental to the board's compressive, flexural, and tensile strength.

2. Physical Reinforcement: The Fibrous Network

The chemical matrix is brittle on its own. To provide the necessary tensile and flexural strength (resistance to bending and breaking), MSB is reinforced with fibers.

Glass Fiber Mesh: Most MSB features a double-layer of alkali-resistant glass fiber mesh embedded on both surfaces. This mesh acts like the "rebar" in concrete, absorbing tensile stresses and preventing crack propagation. When the board is subjected to bending forces, the mesh on the tension side holds the matrix together, significantly enhancing its flexural strength and impact resistance.

Organic/Plant Fibers: Some formulations include dispersed organic fibers (e.g., wood pulp, bamboo fiber) within the core slurry. These micro-fibers create a 3D random network that provides micro-reinforcement, improving toughness, crack resistance, and handling strength before the board is fully cured.

3. The Filler System: Functional Modifiers

The board's core contains inorganic fillers like perlite, vermiculite, and silica sand.

Density and Stiffness Control: While lightweight fillers like perlite reduce density, they are still rigid particles that are locked into the MOS matrix. They contribute to the overall stiffness and compressive strength of the board by filling space and creating a composite material.

Synergy with the Matrix: These fillers are not inert; they are physically and chemically bonded by the MOS crystals. This creates a cohesive composite where the load is distributed evenly between the binder and the filler particles.

4. The Curing Process: Achieving Final Strength

Strength is developed and optimized through a controlled curing process.

Hydration and Crystallization: After forming, the board is cured under specific temperature and humidity conditions. This allows for the complete and gradual formation of the strong 5·1·7 crystalline phase throughout the board.

Avoiding Weak Phases: Proper curing prevents the formation of weaker, less stable crystalline phases that can lead to long-term strength regression and efflorescence (the white, powdery residue seen on some inferior panels).

5. The Composite Effect: The Sum of All Parts

Ultimately, the high strength of magnesium sulfate board is a classic example of a composite material

The Lightweight MGO Board with

The Lightweight MGO Board with

Analysis of Magnesium Sulfate

Analysis of Magnesium Sulfate

Why Choose Magnesium oxide (Mg

Why Choose Magnesium oxide (Mg