Why Choose Magnesium oxide (MgO) panels?

Why Choose MgO Panels?

MgO panels have gained traction across residential, multifamily, and commercial sectors thanks to their strong performance in the following areas:

1. Durability

Dense and abuse-resistant, MgO panels are built to endure the rigors of transport and on-site handling. They resist cracking, chipping, and damage during construction.

2. Dimensional Stability

Unlike wood or gypsum-based products, MgO panels resist warping, swelling, and delamination – even in high humidity and during high temperature fluctuations.

3. Non-Toxic Composition

Free from harmful chemicals like heavy metals, arsenic, formaldehyde-based resins, and other anti-microbial additives, MgO panels are safe to cut and handle when installing and support healthy indoor air quality.

4. Crystalline Silica-Free

MgO panels contain minimal to no crystalline silica, meaning they are worker-friendly and safe to cut without risk of breathing in harmful materials.

Key Performance Advantages

Fire Resistance

With a majority of their weight consisting of non-combustible MgO cement and chemically-bound water molecules, MgO panels are ideal for buildings requiring enhanced fire safety – especially in wildfire-prone areas or code-regulated urban settings. Varieties of MgO panels are suitable for use in all construction types (I–V), helping to achieve fire ratings in exterior and interior assemblies.

Moisture Resistance

Capable of withstanding exposure to rain, snow, and freeze-thaw cycles for several months during construction, MgO panels are an excellent safeguard against weather-related delays. Even under harsh conditions, MgO panels will not swell or deteriorate like traditional sheathing products.

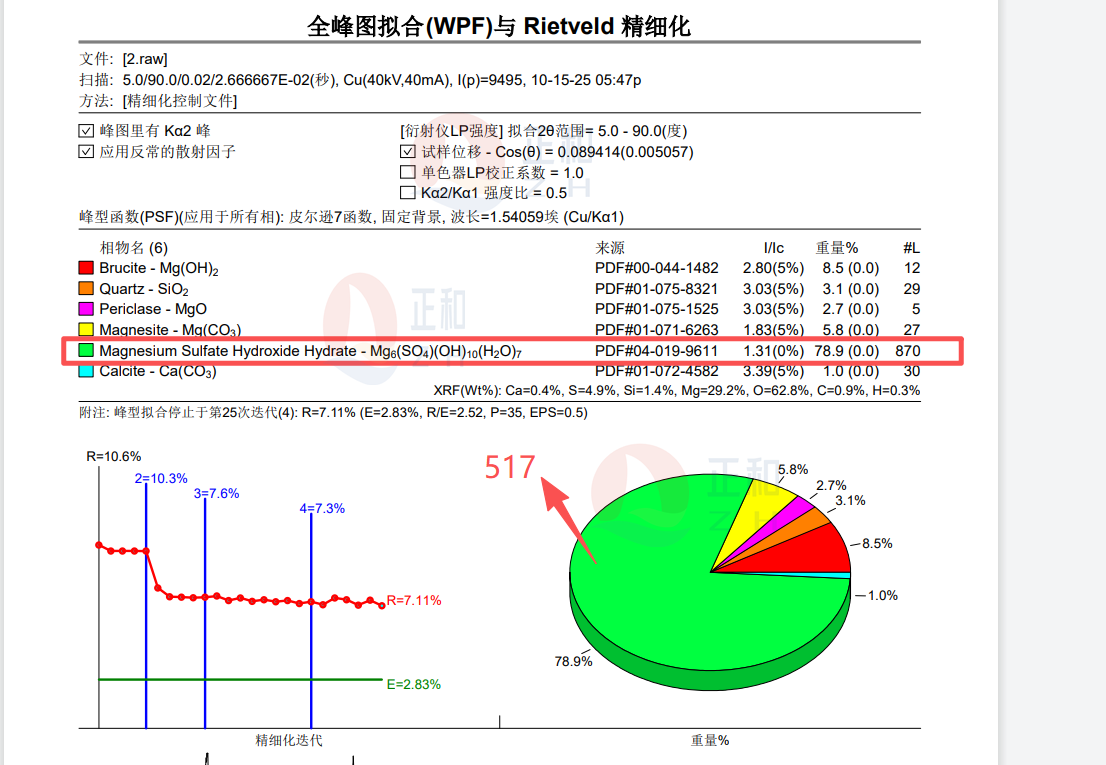

Analysis of Magnesium Sulfate

Analysis of Magnesium Sulfate

Why Choose Magnesium oxide (Mg

Why Choose Magnesium oxide (Mg