Benefits of Incorporating EPS Particles into Magnesium Sulfate Boards

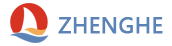

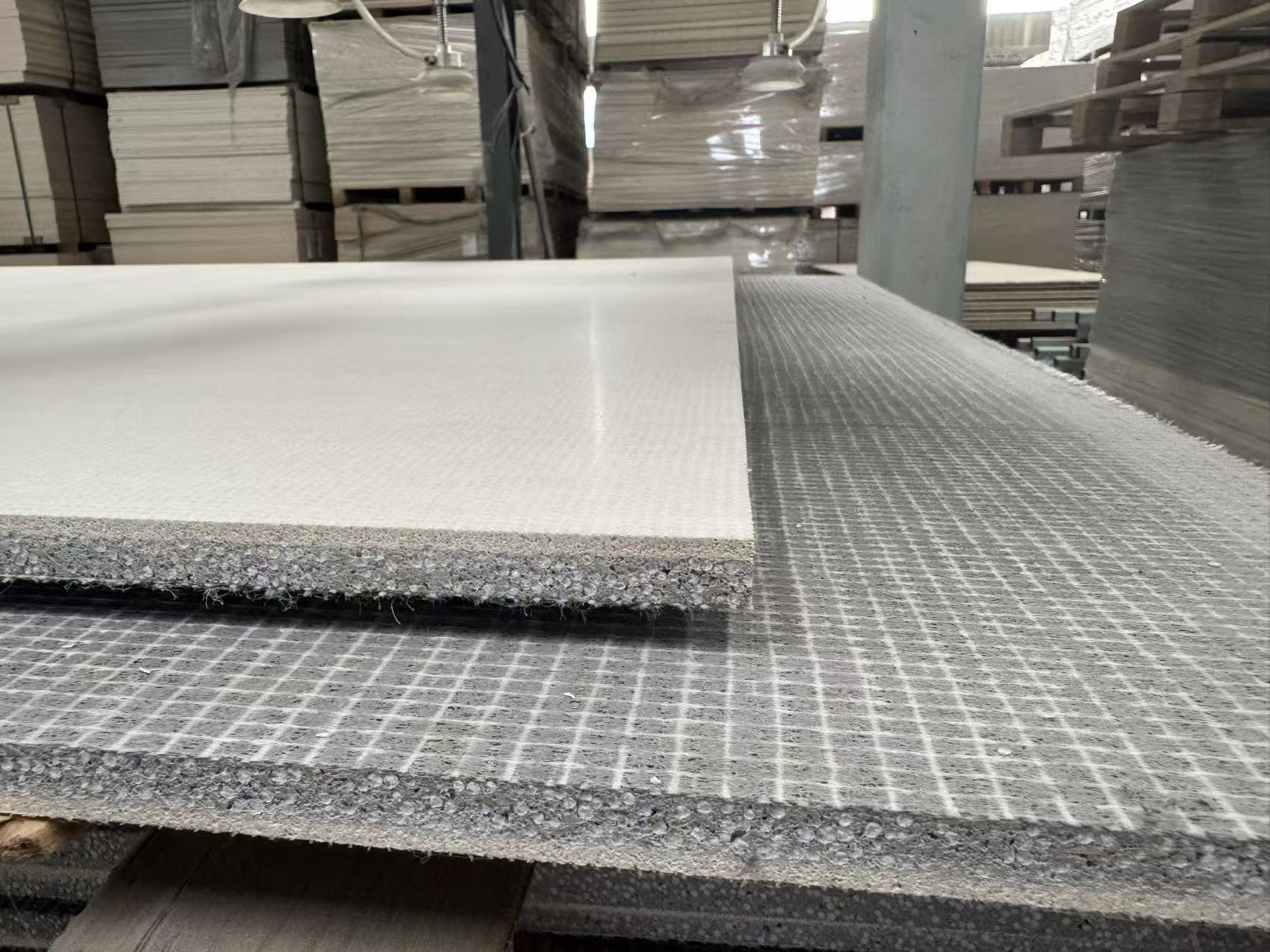

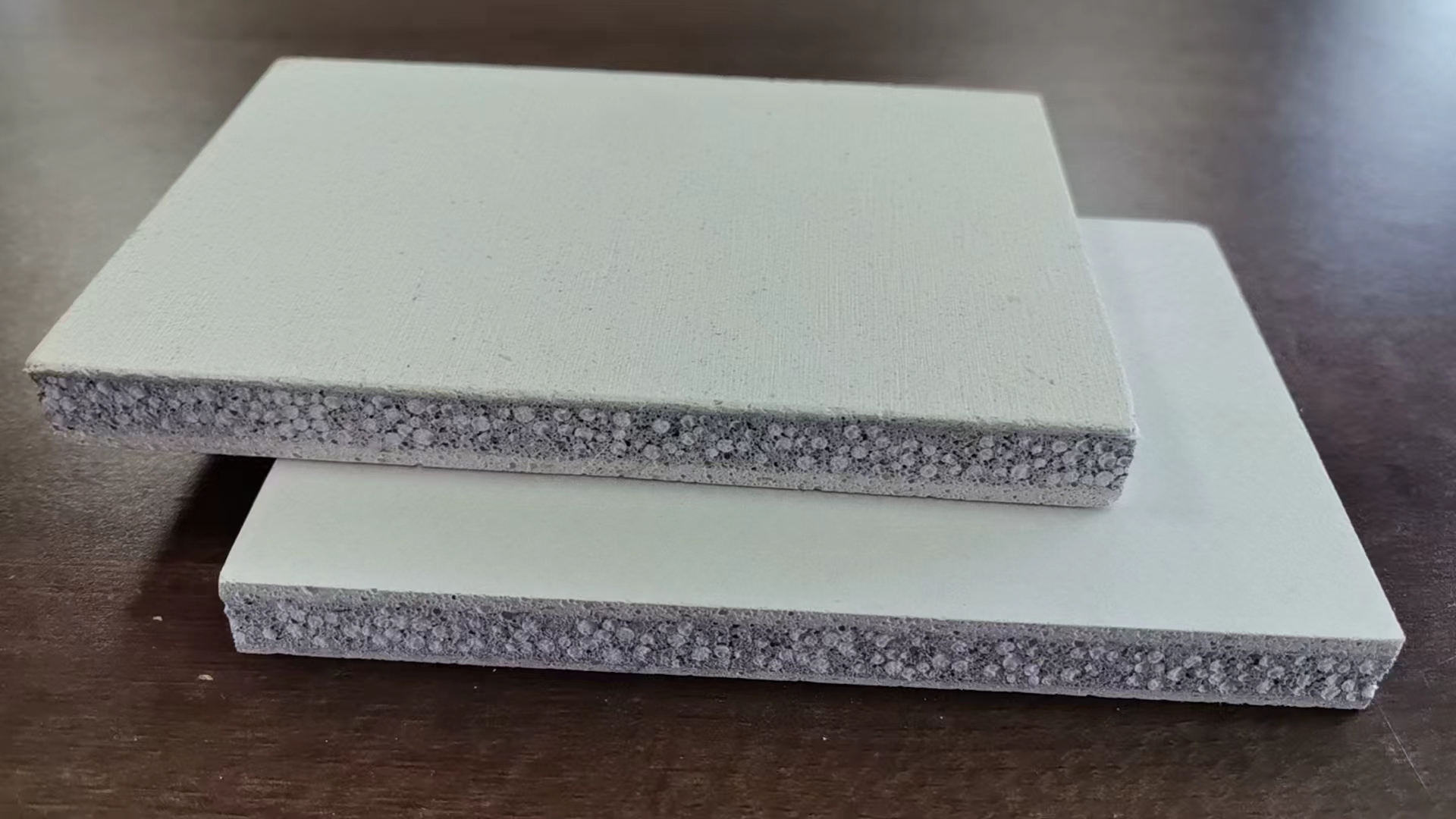

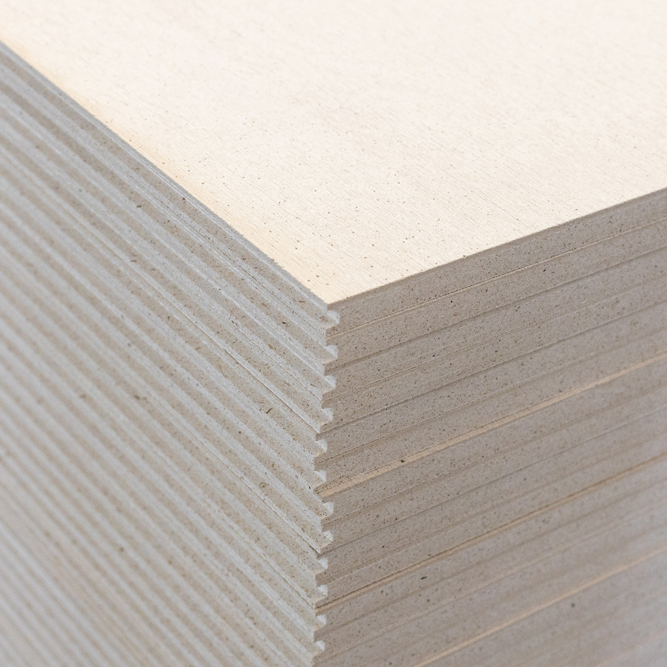

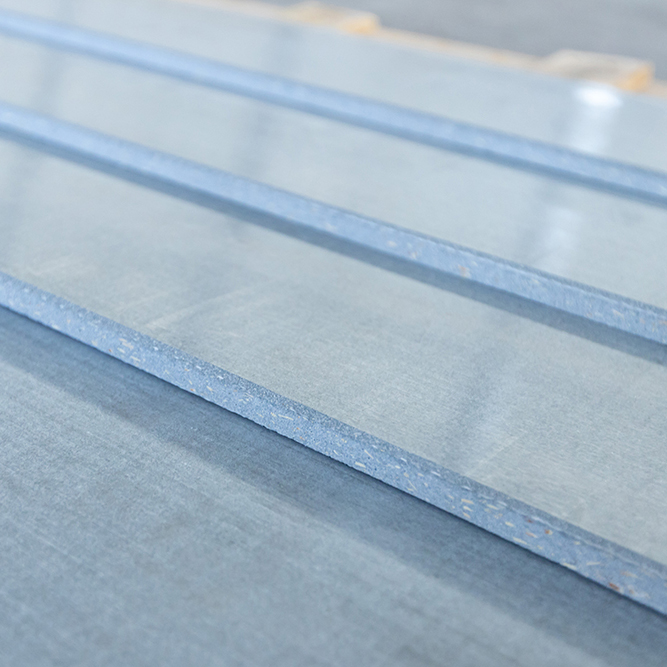

Magnesium sulfate boards, a type of magnesium oxide (MgO) cement-based panel, are valued in construction for their fire resistance, strength, and environmental profile. The incorporation of Expanded Polystyrene (EPS) particles into the matrix of these boards creates a composite material with significantly enhanced properties. This modification transforms a standard board into a lightweight, multi-functional panel with broadened applications.

1. Significant Reduction in Weight

This is the most immediate and impactful benefit. EPS beads are composed of over 95% air, making them extremely lightweight.

Mechanism: The EPS particles displace the much denser cementitious paste, lowering the overall density of the cured board.

Advantages:

Easier Handling and Installation: Lighter boards reduce labor fatigue, speed up the installation process, and lower manual handling risks.

Reduced Structural Load: The decreased dead load on the building's structure allows for more flexible architectural designs and can lead to cost savings in structural support elements.

2. Enhanced Thermal Insulation

EPS is a well-known and effective insulating material due to its closed-cell structure, which traps air and minimizes heat transfer through conduction and convection.

Mechanism: The dispersed EPS particles create a multitude of insulating pockets within the board, drastically reducing its thermal conductivity (k-value).

Advantages:

Improved Energy Efficiency: Buildings using these composite panels require less energy for heating and cooling.

Condensation Prevention: By maintaining surface temperatures closer to the interior ambient temperature, they reduce the risk of condensation and associated mold growth.

Multi-functional Application: The board acts as both a structural sheathing/cladding and an insulating layer, simplifying the building envelope.

3. Improved Workability and Nailability

The inclusion of lightweight, compressible EPS particles changes the physical nature of the hardened board.

Mechanism: The composite becomes less brittle and more forgiving than a pure, high-density magnesium sulfate board.

Advantages:

Easier Cutting and Shaping: The material is less likely to chip or crack during cutting with standard tools.

Better Fastener Retention: Screws and nails can be driven in more easily and are held more securely without causing large cracks, as the EPS particles allow for some compression around the fastener.

4. Maintained Inherent Fire Performance (with Formulation Control)

While EPS is a thermoplastic and combustible on its own, its behavior within the magnesium sulfate matrix is different.

Mechanism: The magnesium sulfate cement itself is inherently fire-resistant and non-combustible. In a fire, the cementitious matrix forms a protective char layer that shields the embedded EPS particles from heat and oxygen. The EPS will melt and vaporize only when the intense heat penetrates this layer, and the process can absorb energy.

Advantages: With the correct particle size, distribution, and cement-to-EPS ratio, the composite board can still achieve excellent fire resistance ratings, often far surpassing standard EPS foam boards and competing favorably with other composite panels.

5. Dimensional Stability and Crack Resistance

The lightweight nature and the physical properties of EPS can contribute to improved stability.

Mechanism: The reduced density leads to lower shrinkage stresses during the curing and drying process. The flexible nature of the EPS particles can also help to micro-crack bridging within the matrix.

Advantages: This results in a more stable panel with less warping and a lower propensity for shrinkage cracking over time.

Summary and Conclusion

In summary, the strategic addition of EPS particles to magnesium sulfate boards creates a superior composite material that addresses several limitations of the standard board. The primary trade-off is a reduction in pure mechanical strength and density, but this is often an acceptable compromise for the target applications.

Benefits of Incorporating EPS

Benefits of Incorporating EPS

1. What exactly is Zhenghe Mag

1. What exactly is Zhenghe Mag

2. What is 517? What is the 5

2. What is 517? What is the 5

3、Why does the Zhenghe MGO boa

3、Why does the Zhenghe MGO boa